Programvare for skilt og etiketter

Programvareutviklingssett (SDK)

Merking og avlåsing og hengelåser

Rørmerker og ventilidentifikasjon

Installasjonsteknikk (på engelsk)

Produktidentifiseringsløsninger

Kabel- og ledningsidentifiseringsløsninger

Løsninger for sikkerhet på arbeidsplassen

Løsninger for identifisering i laboratorier

Skriv ut dine egne produktidentifiseringsløsninger

RFID-etiketter / Smart merking

Merkingsautomasjon og integrering av etikettutskrif

Gjør det sikrere å utføre arbeid på maskinene

Implementer avlåsing/merking i verdensklasse med en global ekspert

Handle avlåsing/merking-produkter OPPDAG VÅRE TJENESTER FOR AVLÅSING/MERKING

Maksimer sikkerheten på arbeidsplassen og beskytt arbeiderne med vår komplette løsning for avlåsing/merking.

Vi samarbeider med produsenter over hele verden for å optimalisere eksisterende og implementere nye avlåsingsprogrammer fra bunnen av.

Hva er avlåsing/merking?

Avlåsing/merking hindrer ulykker på arbeidsplassen ved å fullstendig og midlertidig isolere maskiner fra energikilder. Prosedyren og tilknyttede verktøy stopper maskinbevegelse og hindrer at maskinene slås på igjen for tidlig mens det pågår vedlikehold.

Avlåsing/merking kan effektivt forhindre vedlikeholdsulykker tilknyttet maskinenergi og bevegelige maskindeler. I tillegg vil den visuelle tilstedeværelsen på arbeidsplassen fostre en sterk sikkerhetskultur som tar sikte på at alle ansatte skal komme trygt hjem hver dag.

Hent inspirasjon fra vår gratis veiledningsbok om hvordan du best implementerer avlåsing/merking.

Ekspertveiledning om dine behov for avlåsing/merking

Effektivt firetrinnsprogram for avlåsing

Følg den beste globale øvelsesplanen for å lage et effektivt avlåsingsprogram.

Lær mer

Overholdelse av avlåsing/merking

Retningslinjer for avlåsing/merking: respektere lovmessige krav.

Lær merVideoer med beste praksis for avlåsing/merking

Se opplæringsprogrammet vårt for avlåsing/merking.

Se nåEn fullstendig implementering av avlåsing/merking fra A til Å

Optimaliser enkelt eksisterende programmer eller implementer avlåsing/merking i verdensklasse fra bunnen av med vårt komplette tilbud. Uansett hva du vil gjøre med programmet for avlåsing/merking, kan Brady gi deg støtte og veiledning.

Klasseledende prosedyrer

Gjør raskere klart til sikrere vedlikehold på maskinene mens du føler deg helt trygg med våre tjenester for avlåsing/merking. Sikkerhetsteknikere fra Brady kan besøke anlegget ditt for å identifisere alle energiisolasjonspunktene på maskinene og lage illustrerte, maskinspesifikke prosedyrer for avlåsing/merking basert på beste praksis globalt.

Prosedyrene til beste praksis for avlåsing/merking veileder de ansatte gjennom en rekke trinn for midlertidig og fullstendig å isolere en maskin fra energiforsyningen og låse den i denne isolerte tilstanden mens vedlikeholdet pågår.

Oppdag våre tjenester for avlåsing/merking

Blokker tilgang til alle energistyringspunkter

Tilgang til energiisolasjonspunkter kan blokkeres midlertidig med vår komplette serie dedikerte enheter for avlåsing/merking.

Energiisolasjonspunkter kan for eksempel være sikringer, knapper, ventiler, hjul, spaker og andre systemer som styrer strømmen av mekanisk, elektrisk, hydraulisk, pneumatisk, termisk, tyngdekraftsbasert og lagret energi, samt kjemikalier i væske- og gassform, varme overflater og stoffer. Alle disse kan slås av, og tilgang kan låses mens vedlikehold pågår.

Ring oss for å få de beste løsningene for energiforsyning på dine maskiner, eller se gjennom vår omfattende katalog.

Optimal prosedyrehåndtering

Ha full kontroll over prosedyrene for avlåsing/merking, selv på flere forskjellige anlegg, med vår LINK360-programvare. Prosessen med håndtering, oppretting, oppdatering, gjennomgang, skalering og kommunisering av visuelle avlåsingsprosedyrer som er lette å følge, skjer med bare noen få klikk

Du kan enkelt skrive ut prosedyrene og påføre dem på den aktuelle maskinen, eller sende dem til relevante ansatte via telefon og nettbrett for trinnvis overholdelse ved hjelp av LINK360-appen.

Oppdag LINK360-programvare

Verdens beste sikkerhetshengelåser

Lås enkelt avlåsing/merking-enheter på plass og sørg for at maskinen er isolert på en effektiv måte inntil alt vedlikeholdsarbeid er ferdig. Brady tilbyr sikkerhetshengelåsprodukter av høy kvalitet som kan passe inn i ethvert program for avlåsing/merking.

Våre unike SafeKey-hengelåser til avlåsing/merking har 700 % flere lås- og nøkkelkombinasjoner enn noen annen sikkerhetshengelås på markedet. De muliggjør omfattende, fremtidssikre programmer for avlåsing/merking, har alle nøkkelholdingsfunksjon og er tilgjengelige i optimaliserte versjoner som passer perfekt til dine bruksområder innen avlåsing/merking.

Se hvilke alternativer som finnes i vår veiledning til valg av hengelåser, eller ta kontakt med oss for å diskutere hva arbeidsplassen din trenger.

Sikkerhet er personlig

En sikkerhetshengelås er ofte den siste hindringen som beskytter mot for tidlig igangsettelse av maskin og en eventuell vedlikeholdsulykke med alvorlige konsekvenser for personalet. Vi kan tilpasse hengelåsenes utseendefor eksempel ved å trykke bilder av personer direkte på låsen for å tydelig vise at den beskytter livet til en kollega.

Pålitelige tags som varer lenge

Kommuniser enkelt at vedlikehold pågår med tags for avlåsing/merking som kan tilpasses fullstendig. Vi kan trykke og tilpasse enhver tag til et bilde, en indikasjon på hvem som har låst energistrømmen, et telefonnummer eller til og med en dato for når det er forventet at vedlikeholdet vil være fullført. All ønsket informasjon trykkes på et robust vinylmateriale som motstår varme, skitt og en rekke kjemikalier.

I tillegg kan du ha fullstendig kontroll over utskriften av tags med en praktisk sikkerhetsskriver med blekkpatron på anlegget, som fullfører delvis trykte eller blanke ruller med tagmateriale.

KJØP tags for avlåsing/merking

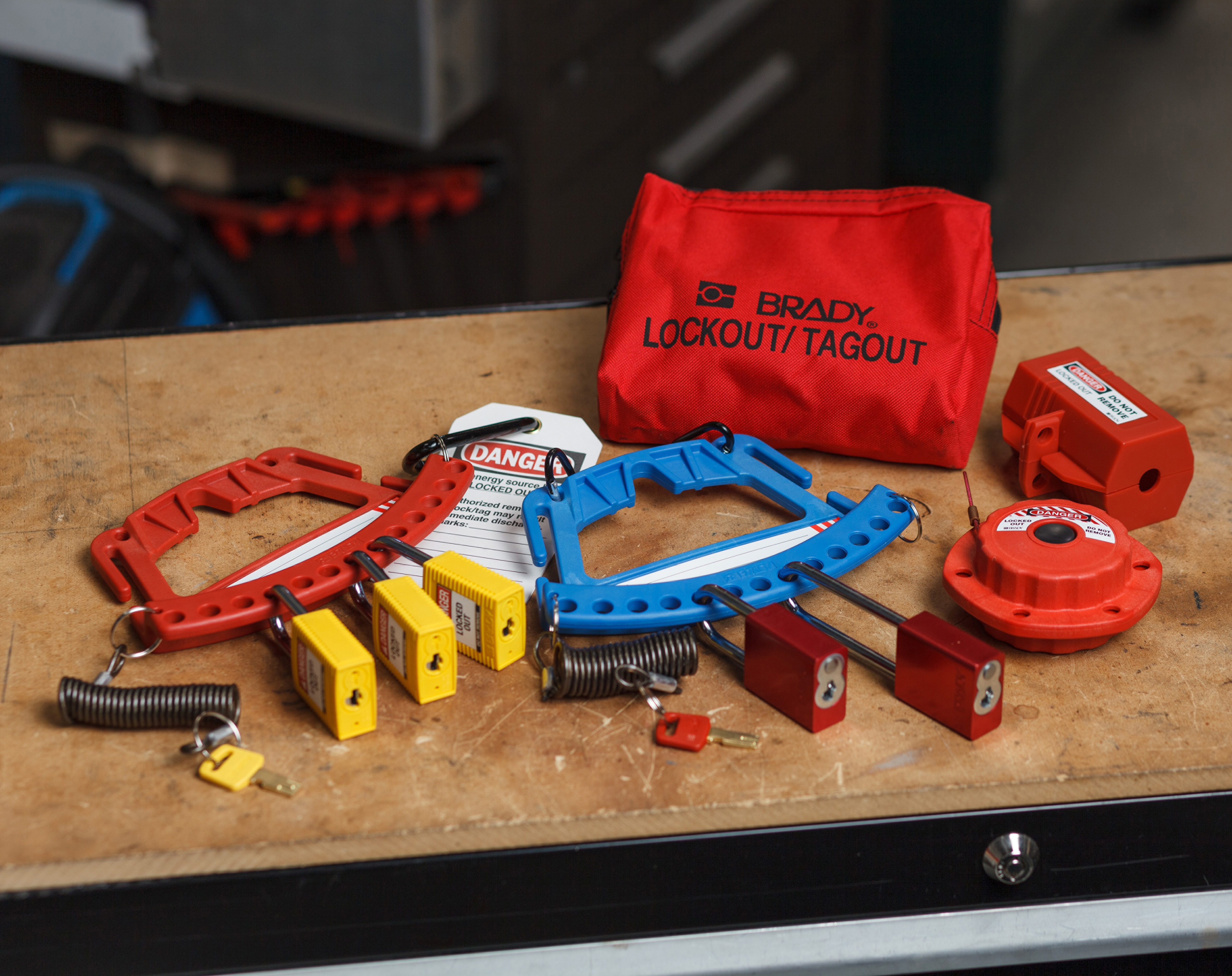

Effektivt tilbehør

Støtt effektiv bruk av avlåsing/merking på din arbeidsplass med praktisk tilbehør. Hasper, for eksempel, gjør det mulig for flere vedlikeholdsarbeidere å feste sikkerhetshengelåsene sine på en enhet for avlåsing/merking. Tilpassede avlåsingssett og vesker gjør det enkelt å bære med seg standardiserte verktøysett. Dette kan enkelt bestilles hvor som helst i verden. Låskassene våre gir også sikkerhet for avlåsing/merking i store vedlikeholdsoperasjoner som kan omfatte flere arbeidsskift fra ulike team.

KJØP avlåsingsenheter

Svært synlig verktøysfordeling

Gjør alle relevante verktøy for avlåsing/merking lett tilgjengelige på arbeidsplassen med tilpassede verktøypaneler.

Verktøypaneler oppfordrer til å bruke de riktige løsningene og returnere dem til riktig sted etter at vedlikeholdet er fullført. De reduserer drastisk tiden som brukes på å lete etter verktøy og forbedrer tilgjengeligheten for avlåsing/merking på arbeidsplassen betydelig. I tillegg bidrar de godt synlige verktøypanelene for avlåsing/merking til å fremme en sikker arbeidskultur i ethvert arbeidsmiljø.

KJØP verktøypaneler & tilbehør

Vi er her for deg

Uansett hva du vil gjøre med programmet for avlåsing/merking, kan Brady gi deg støtte og veiledning. Vår fullstendige løsning for avlåsing/merking omfatter innovative hengelåser med omfattende nøkkelplanlegging, dedikerte avlåsingsenheter, praktisk programvare og flotte tjenester,deriblant identifikasjon av energikontrollpunkter og den beste prosedyreprogrammeringen i klassen.

Oppdag vår fullstendige løsning for avlåsing/merking

En erfaren, global partner

Brady Corporation er en av de største leverandørene av løsninger for avlåsing/merking. Vi jobber både med store og små bedrifter for å fremme ambisjoner om Go for Zero og etterlevelse av lovkrav om sikkerhet på arbeidsplassen i hele verden. Vi tilbyr våre kunder å ta del i denne globale erfaringen ved å integrere beste praksis fra hele verden og tilpassede løsninger i vårt tilbud for avlåsing/merking for å bidra til å forhindre vedlikeholdsulykker forårsaket av maskinenergi eller maskindeler i bevegelse.

KONTAKT OSS FOR Å DISKUTERE HVILKE BEHOV DU HAR